Research is now out with a new hybrid material that will eliminate the high energy consuming, gas separation process, thus helping oil and chemical companies save a good amount of money. Jeffrey Long and his team at the University of California, Berkeley, has created an iron based material that helps to achieve high temperatures, efficiently separating gases while eliminating the chilling process.

At present if one wants to separate hydrocarbon gas mixtures into pure chemicals for making plastic, crude oil is heated up to 600 degree Celsius and complex hydrocarbons are broken down into lighter and more short chain molecules. This gaseous mixture is then cooled 100 degrees below zero, where it liqudifies and divided into gases used for plastic. But, the ugly side of cryogenic distillation at low temperatures is its contribution to global climate change.

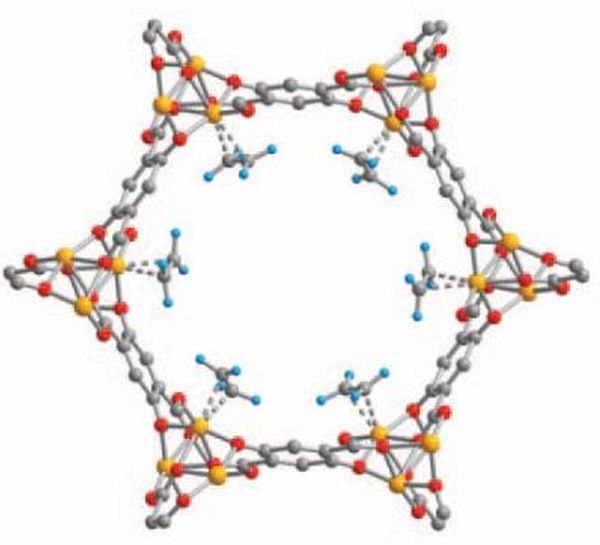

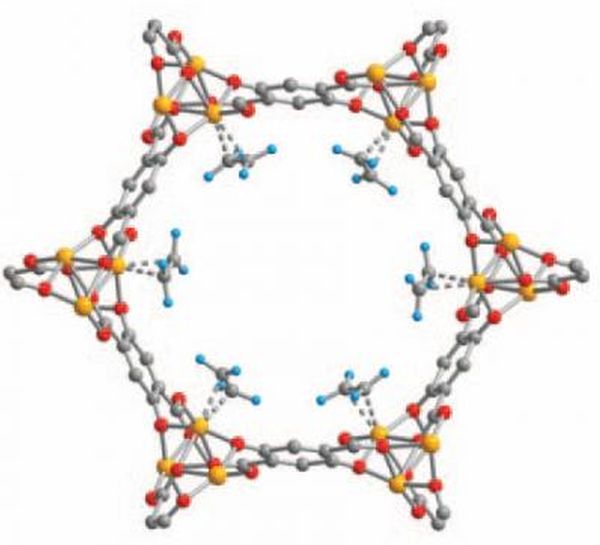

As a solution to this, an iron based material, a metal organic framework (MOF) has been developed and it will eliminate the chilling process altogether, facilitating separation at higher temperatures.

MOFs are good for purifying natural gases, removing all impurities. The basis for separation is that MOFs have a large surface area for gas to integrate with. It contains iron atoms that will bind unsaturated hydrocarbons allowing ethylene, propylene and acetylene to stick with iron much more strongly than other compounds like propane, methane or ethane.

Via: Newscenter