Human activities have led to the devastation of the Planet’s environment affecting lives of all its inhabitants. Efforts are on to mitigate this damage, and as a result several new methods that can reduce the damage are showing up. This involves being sustainable at every stage of our life including the way we design our homes and the materials that we use in construction.

There has been tremendous research and development brought about in this field and the day is about to come when builders will make homes with built-in insulation and molded bricks. This is a very important step because any construction process requires large amounts of natural resources, generates huge quantities of waste, and also the traditional process of manufacturing bricks and insulation work makes use of too many resources.

According to a report by The U.S. Environmental Protection Agency, commercial buildings are solely responsible for 40% landfill wastes. Construction industry contributes to 40% of global carbon dioxide emissions. To cope with such unflattering figures, it is essential that the various building construction industries, along with scientists and entrepreneurs generate products that can dramatically reduce their share of pollution.

The recently held Cradle to Cradle Product Innovation Challenge Show has clearly proved that buildings construction can be sustainable to a great extent just by use of the various renewable biological resources. These buildings incorporate safe materials that require renewable sources of energy and are full recyclable.

The company bioMason has successfully developed a process of making bricks from bacterial byproducts. These byproducts hold together the sand particles with a force that is strong enough to be use for building a house. Bacteria made natural cement is all set to be transformed into a coral brick within just five days and that too without the use of heat and other raw materials that are generally used to make masonry brick where 40 % cost is due to the fuel required for kiln firing. This amazing bio-brick can be made using waste materials such as urea and common bacteria.

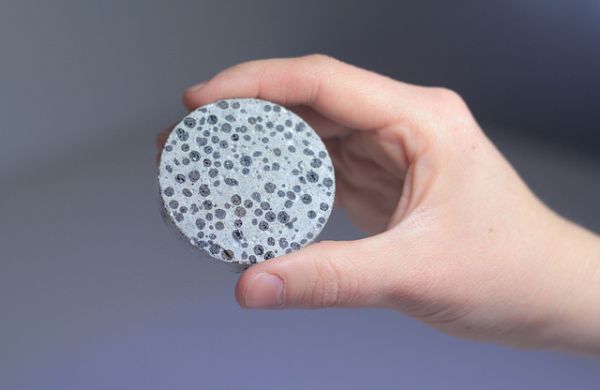

Another great innovation goes to the credit of the company Ecovative for creating a mushroom insulation material made by using plant stalks, seed husks that are held together using mycelium which is a material of fungal origin. Fungus which is either grown inside a mold or within the wall cavity provides a strong insulation for the walls and can even be brought to use in the form of spray-on foam insulation. This fungal insulation is compostable and fire proof and is free from formaldehyde and other toxic volatile chemicals.

The latest innovation in the green building material research involves the development of self healing concrete, which is made by using bacteria that multiply and grow under dry climatic conditions. These bacteria when mixed with the concrete release calcium carbonate, a waste material generated by the bacteria itself. This calcium carbonate gets filled in the cracks and crevices of the concrete thus increasing its strength and reducing the costs of maintenance.

Summary

The efforts in making the environment better can include numerous changes brought about in the traditional practices followed by construction industry. Self-healing concrete can go a long way in reducing the copious amount of waste and pollution resulting from construction activities.