Petroleum is an ingredient used in many modern products ranging from pharmaceuticals to plastics. Once the sources of petroleum have been exhausted, how are we going to produce the petroleum based products to meet our demands? The answer is given in the research published by Professor Krijn de Jong and his team.

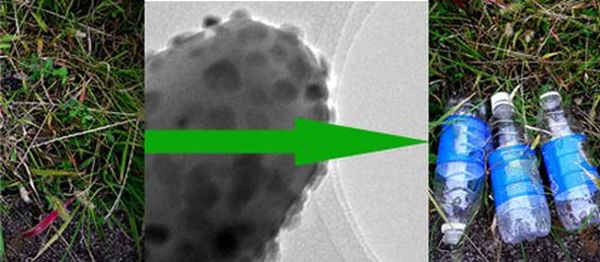

These scientists in collaboration with Dow Chemicals, discovered a process to make chemical raw materials from biomass. The main element is nanocatalyst, which is produced when 0.00002 millimeters of iron particles are stabilized on carbon nanofibers. SynGas, a gaseous mixture of hydrogen and carbon monoxide synthesized from biomass, is passed across the catalyst, converting it into useful end products, ethylene and propylene.

The series of reactions that result in the conversion is called the Fischer – Tropsch process. The process can be implemented on crop remains, grasses, trees,etc. Instead of depending on limited raw materials to create plastic, companies can use discarded non consumable biomass for bioplastics.

The end products of the SynGas reaction are more advantageous as they do not pose health hazards. Petroleum contains many carcinogenic and other harmful components that make it unsafe to work with unless it is properly cleansed. Though ethylene and propylene molecules are similar in structure to petroleum derivatives, they are devoid of the harmful components that make petroleum.

The research is still in the testing stages, scientists still need to understand the risks and possibilities of the conversion method, the cost involved and other factors before it can be adopted on a wider scale.

Meanwhile, bioplastics continue to face hurdles with regards to pricing, performance, high standards of biodegradability and other issues. Nevertheless, they remain the prime eco friendly choice that can replace the environment damaging plastics.

Via: TreeHugger