The main reason why plastic is becoming so problematic is that it is immensely useful. We are using it in almost every sphere of life. In fact, no matter wherever you look, it is almost impossible to not find plastic there. Now more than ever we are facing the dilemma. Should we stop using plastic and curb our economic growth or should we keep on using it and destroy the environment? In this debate, companies are coming up with alternatives to plastic. Out of all these alternatives, bioplastic is standing in the front. If it works, in future years, it might take the place of plastic. However, with it too, there are many complications.

The Good, the bad and the ugly of Bioplastics

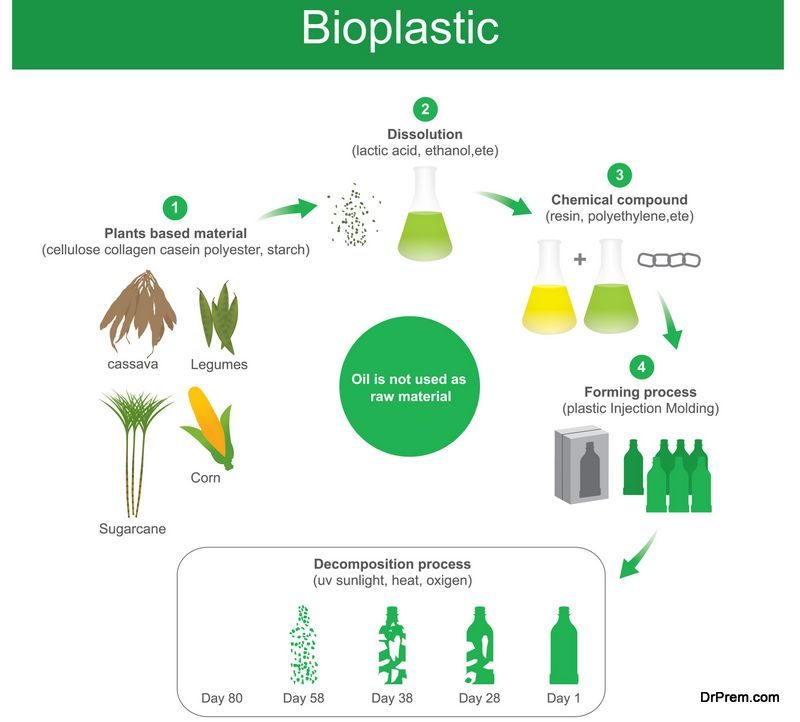

With the ever-increasing awareness of the environment as well as the health hazards of oil-derived plastics, the global industry is taking into consideration the plant based alternatives (aka Bioplastics). Bioplastics consist of renewable materials like starch from corn, potato etc., soy protein, cellulose and lactic acid. Unlike synthetic plastics, bioplastics are non toxic. Moreover, one can easily decompose most of them to form water, biomass and little amount of carbon dioxide. Biofuels are not new. They have been there for years. However, owing to the lack of popularity of plastic, they are becoming popular for the commercial applications over the last decade.

The other factors to this include environmental problems and the mounting cost of oil. Bioplastics have a number of advantages over their synthetic counterparts. On the other hand, there are some concerns too. Let’s take a detailed look at the pros and cons of the ‘sustainable’ bioplastics.

The good:

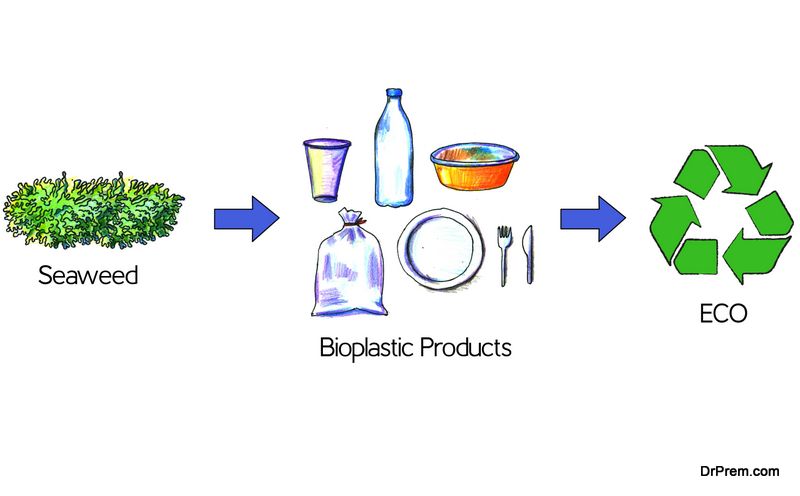

Bioplastics are perceived to be environmental friendly and hence, the range of their applications is expanding. These biodegradable plastics are nowadays being extensively used to make shopping bags, packaging, cutlery, mulch film, food service products, fishing nets and many more such products. This polymer is emerging in markets because this material is non toxic and eco friendly. Biomass including trees plants and other organic materials, all of which are renewable, are required to manufacture bioplastics.

Bioplastics are perceived to be environmental friendly and hence, the range of their applications is expanding. These biodegradable plastics are nowadays being extensively used to make shopping bags, packaging, cutlery, mulch film, food service products, fishing nets and many more such products. This polymer is emerging in markets because this material is non toxic and eco friendly. Biomass including trees plants and other organic materials, all of which are renewable, are required to manufacture bioplastics.

The biodegradable plastics are further decomposable and if not recycled, it gets absorbed in the earth in very less time. The break down process is also faster, giving off biomass and water, and minimum amount of harmful carbon emissions. Their manufacturing process does not cause any damage to the environment as there is little emission of greenhouse gases and the manufacturing process requires around half of the energy required to manufacture their non biodegradable counterparts.

Can this be better?

Utilizing biodegradable plastics have various ecological benefits. Without adding much of harmful content to the atmosphere, they are made up in a much cleaner way than the traditional plastics. In contrast to conventional plastics, which make use of fossil fuel i.e. petroleum, the bioplastics do not depend on these non renewable oils for their production. After being discarded these bioplastics are molded into water and organic content that mingles in the soil and make it healthier. The future seems great and promising for the bioplastics if few of the things, including the cost effectiveness and the disposal issues, could be addressed in a proper way.

The bad:

Though these plant-based plastics may apparently be green for the eco-aware people, as they depend on biomass for their production, but the fossil fuels required to provide energy for their manufacturing, make them not so green. These materials can be composted only inside the composting industries and not in homes. The accessibility to these industries can be a problem as such facilities are limited in the countries.

Bioplastics are made out of biomass that has to be cultivated. Genetically modified corn and soybean, which are mainly used as biomass, have to be fed with toxic pesticides thus contributing to environmental as well as soil pollution. Although, the Oxo-Biodegradable plastic bags that consist of small bits of harmful metals like manganese, cobalt and iron are compostable, but the metal leftover may pose danger to the environment. Moreover, the plastic bags made of bioplastics are not as strong as the regular plastic bags and also have problems with moisture, limiting the use of bioplastics

Can this be avoided?

There are various methods of producing bioplastics. That is why the compostable plastics vary in their capabilities and properties. Almost all of these make use of renewable and organic components for manufacturing of biodegradable plastics. Moreover, the bioplastics market is quite small as of now. Therefore, the issues remain with the disposal, as the composting facilities are not everywhere. Scientists are trying to find out various methods to make these bioplastics more cost effective as well as eco friendly.

The ugly:

Bioplastics are required to be separated from the other plastics before they are recycled. These plastics, if are not chucked out in a proper way, will contribute more rubbish in the waste streams. The inappropriate means of decomposing will entail toxins like methane, carbon dioxide and ozone depleting chemicals to the atmosphere. The eco toxicity will also be contributed by carcinogens, acidifications etc., which mostly come from the pesticides and fertilizers used for processing bioplastics.

Bioplastics are required to be separated from the other plastics before they are recycled. These plastics, if are not chucked out in a proper way, will contribute more rubbish in the waste streams. The inappropriate means of decomposing will entail toxins like methane, carbon dioxide and ozone depleting chemicals to the atmosphere. The eco toxicity will also be contributed by carcinogens, acidifications etc., which mostly come from the pesticides and fertilizers used for processing bioplastics.

Why are we so critical?

With the rising environmental concerns and the shrinking oil supply, bioplastics are being considered as a good alternative. Although, the bioplastics are not being used on a large scale owing to the costs associated and a few downsides, they do hold a promising future. Keeping cons aside, it is without doubt a green option to choose bioplastics over regular petroleum based synthetic plastics.

The bottomline

With the ongoing advancements in the bioplastics industry, there seems to be a great potential for improvement. The disposal issues, infrastructure problem and the lack of production facilities or the composting centers could be the major problem for the growth of the bioplastics market. Still, we can’t deny the fact that the bioplastics are here to stay and its share is going to increase in the plastics market in the coming years.

6 Major Trends in Bioplastics

1. Waste chicken feathers converted into bioplastic:

Dr. Yiqi Yang, from the Institute of Agriculture and Natural Resources, at the University of Nebraska-Lincoln, have ingeniously conceived of a new type of bioplastic made out of waste chicken feathers. Now the advantage of this conception is the relative abundance of one of its components i.e. feathers, as proven by this statistical figure – annually, United States alone generates more than 3 billion pounds (appox. 1.36 billion kg) of chicken feathers. The bulk part of it is either processed into animal feed or simply discarded.

2. 100 percent plant-based ‘edible’ plastic:

Melbourne based bio-plastic manufacturer Plantic has come up with a remarkable and rather convenient conception in the form of fully plant based bio-plastics, which can easily degrade in water in just about 20 seconds! The plastics are composed from starch (available from corn); while their paints are also totally non-toxic and derived from natural plant materials (which actually make them pretty much edible). The only downside to this crucial technology can be the presence of humidity and moisture in the air.

3. Making bio-plastics from potatoes!

Plastic from potatoes is set to be the new rage in the ‘green’ market, according to a report put forth by University of Maine’s Margaret Chase Smith Policy Center. Composed from the root portion of the potatoes, such plant based plastics can also prove to economically viable in the long run, as they can be acquired as a by-product of the mushrooming potato chips industry. Moreover, they can be used in various applications, like carpeting, upholstery fabric and recyclable plastic bottles.

4. Growing Plastic in Grass:

Massachusetts-based Biotech Company, Metabolix, has conceived the naturalistic way to manufacture Polyhydroxybutyrate (PHA), a form of bio-plastic. This unique and rather advanced technology literally calls for growing plastics out of leaves of perennial plants such as switch grass. Dubbed as Mirel, such plastics can be used for a plethora of products like credit cards, plastic containers and even vehicle components.

5. Researchers engineer genes of plants to grow raw materials for green plastic:

Extraordinary situations call for extraordinary measures, and that is exactly what researchers from Brookhaven National Laboratory and Dow Agro-Sciences have come up with, in the face of plastic pollution. They have successfully managed to bio-engineer a relative of cabbage with high content of omega-7 fatty acid. Omega-7 fatty acid is one the major components of plastic, and with the naturalistic solution of ‘cultivating’ it, genetically modified seeds can be now be used as a renewable source of chemicals. That in turn can then be used to make greener plastics in the long run.

6. New plant fatty acid-derived plastic can be broken down to diesel-like liquid fuel:

New York’s Polytechnic University researchers led by Professor Richard Gross have contrived a new type of advanced fuel-latent plastic. It has been derived from the components comprising the fatty acids of plants. And the crucial part is that it can be broken down into a diesel-like liquid fuel, which can have significant industrial uses, especially in relation to generators and transportation.

The benefits:

There are a myriad of benefits that can be associated with bio-plastics, namely its convenient virtue of biodegradability (the majority of bio-plastics are biodegradable). The positive quotient on environment, especially in relation to the naturalistic compositions of bio-plastics can make a significant contribution to the state of our overall sustainability. Studies have showed that bio-plastics represent a whopping 42 percent reduction in carbon footprint, because it relies much less on fossil fuel as a carbon source and also introduces fewer, net-new greenhouse emissions if it bio-degrades. Moreover some of the bio-plastic conceptions can even accentuate upon the quality of soil when used in a local scale.

The low down:

The main concern could be over the use of genetically modified organisms (GMO), as there are always possibilities that GMOs could introduce new allergens into the procedures. Adding to that, the whole familiar recycling system has to undergo serious changes. An apt example would be – plastics like PET do not mix with PLA (Polylactic acid plastics from cane sugar or glucose); yielding unusable recycled PET if consumers fail to distinguish the two in their sorting. And lastly, there are some real concerns that the creation of a global bio-economy could contribute to an accelerated rate of deforestation, if not regulated effectively.

The impact:

As already mentioned, the usage of bio-plastics on a massive scale can reduce our emissions by significant levels. Plastic has always proven to be a bane to a sustainable environment, but much because of its economic viability and malleability it has lingered and rather thrived. Now bio-plastic could be that all important alternative to conveniently replace plastic. They can substantially deplete the quantity of hazardous waste caused by oil-derived plastics, albeit in a controlled state. This would certainly add a new ‘green’ dimension to our modern packaging industry, which forms a crucial element of our overall economy.

Some Other Alternatives to Plastic

1. Glass

Plastic is derived from fossil fuels while glass is made out of sand. Hence, glass does not contain any harmful chemicals like plastic. If compared to plastic, glass is easy to recycle. In addition, you can reuse glass for several purposes, including storage containers, candleholders, flower vases, etc, in your home.

2. Liquid Wood

Image Source : Architerials

Liquid wood is a biopolymer that can act and behave just like plastic. However, it is derived from pulp-based lignin and thus, is both renewable and biodegradable. This would make a perfect alternative for those who like the feel of plastic, but still want to protect the environment from petroleum-based products.

3. Jute Fiber

Jute fiber bags are becoming a mainstay in many shopping outlets that have vowed to stop using plastic bags. Apart from being more durable than plastic bags, jute fiber bags are easy to wash and reuse multiple times. You can carry these jute fiber bags while shopping and avoid using the plastic bags offered by stores.

4. Milk Protein

Although milk protein is too hard and brittle for normal use, scientific advancements have led to the creation of milk protein that is more flexible and does not pose risks of cracking when bent. This milk-based plastic can emulate the qualities of petroleum-based plastic, but is biodegradable and thus, eco-friendly.

Although milk protein is too hard and brittle for normal use, scientific advancements have led to the creation of milk protein that is more flexible and does not pose risks of cracking when bent. This milk-based plastic can emulate the qualities of petroleum-based plastic, but is biodegradable and thus, eco-friendly.

5. Corn based plastic

Research in the field of biodegradable plastic alternatives has led to the development of a corn based plastic called polyactides (PLA) which can decompose within just 47 days of landing up in a dump. Made of corn, PLA does not release any toxic fumes when burnt. PLA based plastics can be used for manufacturing cups, containers, utensils and other consumer products.

Research in the field of biodegradable plastic alternatives has led to the development of a corn based plastic called polyactides (PLA) which can decompose within just 47 days of landing up in a dump. Made of corn, PLA does not release any toxic fumes when burnt. PLA based plastics can be used for manufacturing cups, containers, utensils and other consumer products.