Every day we are making new discoveries of human impact on the environment. Earlier, it was just plastic, but now the list is quickly expanding. Even other things which we often think as harmless have a significant environmental impact. After plastic, a new entry to this list of environment disrupting materials is styrofoam. We use it very commonly in insulating pipes for heat and moisture. It is almost indispensable in countries with extremely cold weather. However, owing to its tremendous environmental impact, we would have look for green alternatives to styrofoam insulation.

Green alternatives to styrofoam insulation

Styrofoam is basically extruded polystyrene foam. The material was first discovered by researchers at the Dow Chemical Company, in the year 1941. Styrofoam as an insulator is quite common nowadays. The material is resistive to heat and moisture, and also buoyant. The R-value (a measure of thermal resistance) of Styrofoam is five per square inch. Besides insulation, Styrofoam is useful as a structural material in craftwork and by a florist. As a building material, Styrofoam sheets are placed between concrete slabs to prevent moisture absorption. Furthermore, cylindrical foams help insulate water pipes.

The worst criticisms Styrofoam has gotten are that it is uneconomical to recycle, highly flammable and toxic. The polymer polystyrene, non-foam form of Styrofoam, being a petrochemical compound can emit harmful toxins in the atmosphere. Discarded materials made of polystyrene, including Styrofoam, are non-biodegradable and resistant to photolysis. Styrofoam is made with hydrofluorocarbons; this is the reason why large amounts of carbon dioxide is produced on incineration. Modern builders are reconsidering the traditional method of using Styrofoam materials; instead they are opting for Eco-friendly alternatives to show their allegiance toward a better future.

1. Greensulate

Greensulate is a good alternative to Styrofoam insulation. The material is biodegradable and renewable in nature. Besides being a good insulator, the material is also resistive to fire. You must have seen mushroom being served at your favorite restaurant, but have you ever thought of the idea of mushrooms inside your walls, protecting it from moisture and other environmental hazards. Mushrooms form the basic element in making Greensulate. A mixture of agricultural bio-waste grows mushrooms into shapes to make insulation. One has to add Fungal cells in addition with hydrogen peroxide, to prevent unwanted fungal growth. It is cheaper than polystyrene and more Eco-friendly. This should serve as enough incentives to try this material.

Greensulate is a reality because of the research done by two mechanical engineers – Eben Bayer and Gavin McIntyre. They, along with other members, are now corporate under the name Ecovative Designs that provide Eco-friendly Greensulate materials for a myriad of purposes.

2. Aerogel

Aerogel is a translucent gel-like material that has a higher R-value than Styrofoam. The material has low density and thermal conductivity, and porous in nature. The translucent nature of the material has given it odd names like frozen smoke, liquid smoke, etc. The low thermal conductivity is due to the fact that it negates four ways of heat transfer – convection, conduction, and radiation. Besides insulation, NASA has used Aerogel to collect space dust. Through the process of supercritical drying, the liquid component of the gel is taken out to make the material. The nature of the gel depends on the material from. One can easily extract it. Most common Aerogel materials have silica, carbon and alumina as their constituents. Commercially, Aerogel comes in granular form for insulation and absorption of infrared radiation.

The toxicity of the gel depends on its material. Silica-based Aerogel is not toxic and one can safely use it in homes.

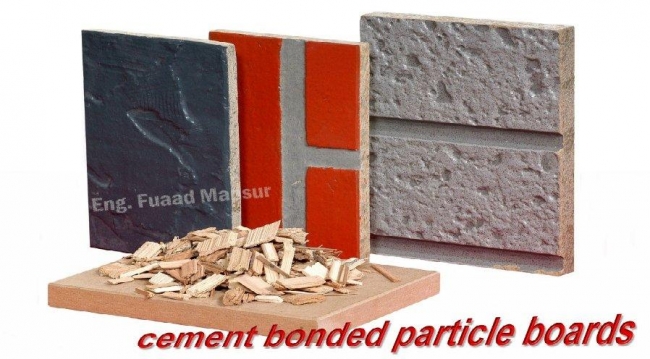

3. Durisol’s green insulated concrete

Durisol, a Canada based company, is the leading manufacturer of cement-bonded wood fiber products. Since 1945, they have been making Durisol products in their 14 manufacturing units located throughout the world. Durisol is the name of the concrete, which constitutes a mixture of wood fiber and Portland cement. It requires 100% recycled wood in the manufacturing process. The origin of the material goes back to Switzerland, where it was invented to provide a cheap building material to rebuild post world war Europe. Currently, the company has a host of Durisol products that include Flat Durisol Sheets, Concrete Wall Accessories, ICF Wall forms and many more.

Durisol concrete forms are cheap, good insulators, Eco-friendly and strong as conventional concrete blocks.

4. Cellulose insulation

People had been using Cellulose insulation in the ancient world, long before the discovery of petroleum. We have now rediscovered the use of such insulation in the wake of environmental crisis. The traditional Cellulose material is purely organic and made from plant fibers, but the modern variant uses recycled newspaper, saw dust, cotton, corncob, hemp and cardboard. Commercially, Cellulose is available in dry loose fill, wet-spray Cellulose, stabilized Cellulose and low-dust Cellulose. The R-value of the material is 3.8 per square inch, little lower than Styrofoam. It is a good insulator for walls, electrical wiring and pipes. A wall filled with Cellulose insulation may have little or no air pockets, thus increasing the efficiency of the insulation. The material is resistive to vapors and molds, and is non-combustible.

The major disadvantage of Cellulose insulation is that it can increase the inflow of dust inside the house.

5. Denim insulation

When talking about Denim, the first thing that comes in our mind is Jeans. Denim insulation is nothing but recycled industrial cotton. Makers of such materials are not going after throw away jeans; rather they are taking the scraps that the textile industry is producing. 85% of the raw material comes from scraps.

The insulation is cheap, 100% recycled, treated with fire-resistant chemicals, and free from VOC and formaldehyde. Furthermore, it’s installation does not require a specialist to meddle in the process.

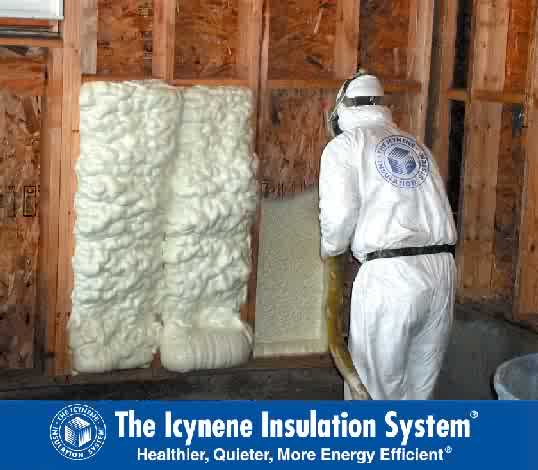

6. Icynene

Icynene is a liquid insulation material that is mixed with water and sprayed through a blower on to the wall. It is made from castor oil. The liquid turns into foam when it hits the wall. The R-value of the material is 3.6 per square inch. It forms an effective air tight layer on the wall, and traps air in bubbles moment it settles down. The air tight feature makes it compulsory to built effective ventilation to assist air flow. Moreover, it allows water vapor to escape hence prevents accumulation of water.

Icynene may not be a viable option for people who are looking for a cost-effective solution to insulation as Icynene is expensive.

7. Straw bale insulation

Straw-bale as an insulator has long been known to us. Straw being an agricultural byproduct is clean and green. The material is fire-resistant and retards sound. In addition, according to popular belief, Bale insulation can reduce 75% of the heating cost. Commonly used bales of straw in construction are derived from rice, wheat, oat and rye. The R-value of the material varies from 0.94 to 2.38 per square inch. Besides being clean, it is also cost-effective.

Straw-bale insulation may not be suitable in extreme cold climates, because of the low R-value.

8. Sheep wool insulation

As the name suggests, the material is made from sheep’s wool. The material is Eco-friendly and comes from a renewable source. It is energy efficient and has an R-value between 3.5 and 3.8 per square inch. Furthermore, the material is also safe for allergy patients. It will make your home green and green homes are more economical, and will also add value to your property. Moreover, it is safe and non-combustible. In addition, installing it is extremely easy and it does not require specialized equipment or safety clothing. It can be fit anywhere in the house as it comes in various shapes and sizes.