The overpowering consumption of fossil fuel is threatening man and earth’s very survival. Owing to the same, companies are shifting to a green way by lessening their product’s dependence on energy consumption and hazardous materials.

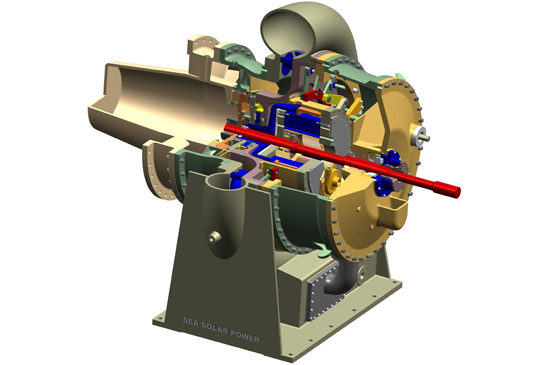

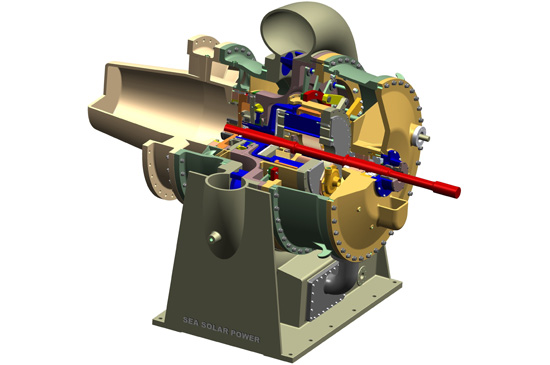

Now, PLM and CAD software is being touted to help firms accomplish their sustainable design goals. Hunting a green engineering dream for more than 30 years, Sea Solar Power Inc. is trying darn hard to turn the concept of sea thermal power into a cost-effective reality by designing cost-efficient power plants that will offer an alternative energy source.

Lately, the compnay has been working to reduce the power source of the plant’s main components to make more efficient the process of harnessing the sun-warmed and colder waters of the ocean to generate electricity. Jim Anderson, vice president of Sea Solar Power cites:

Designing something that’s environmentally friendly doesn’t change the laws of physics or the rules of engineering, it just changes the way you go about thinking about the problem.

It’s not the case only with power plant companies like Sea Solar but, the firms from automotive to electronics and consumer product goods are going green and asking their designers to take into note the environmental concerns when designing new offerings. Moreover, the companies offering consumer goods are being kinda forced to jump aboard the green bandwagon as there is an ever-increasing demand for eco-friendly products in the market.

Kishore Boyalakuntla, national technical manager for analysis products at SolidWorks Inc. and maker of CAD software thinks that all the engineers need to do at this point of time is to design the products with sustainability in mind. They should take into account different things such as usage of alternative materials that would make products easier to recycle or transport. Other thing could be using smallest amount of materials that could be used without compromising with permanence or quality. Above all, there are a number of widely known environmental design practices such as looking for less energy consumption and manufacturing without producing hazardous materials.

CAD and PLM tools assisting engineers

CAD and PLM tools are lately getting a wider attention as they are helping engineers achieve these new design goals. PLM platforms like UGS Teamcenter and PTC’s Windchill offer data management, program management and reporting functions that allows engineers to have access to information on the materials composition of parts in the early hours of the design process thereby assisting in obedience with directives like the European Union’s Restriction of Hazardous Substances Directive (RoHS) and Waste Electrical and Electronic Equipment Directive (WEEE).

CAD tools like Dassault’s CATIA, UGS NX, PTC ProEngineer and Solidworks feature more refined, built-in CAE analysis capabilities that can lend a hand to engineers visualize more green design concepts and test them before creating prototypes. One of the most important things to the idea of sustainable design principles is building a product using a 3D model. Simon Bosley, Inventor product manager at Autodesk Inc. opines that 3D provides a foundation that lets you make calculations and do dynamic simulation so you can see what happens to a design when you change a lever or spring, use a smaller motor or reduce the size of a component.

Companies being benefited:

The finite element analysis (FEA) and thermal analysis in UGS SolidEdge is helping the Sea Solar Power engineering team get the most out of the turbine design much more quickly than if they had to build a new model for every loop from the zero level.

Same is the case with LeBaron Foundry Inc., maker of manhole covers and municipal castings. Because of their typical product design processes, they were confronted by the cost issues. LeBaron started taking benefit from the SolidWorks’ built-in COSMOS simulation tools to figure out where to take materials out of its product without effecting performance. They created a 3D model of the traditional manhole cover and then carved away materials using COSMOS’ analysis of low-stress areas. Interestingly, they were able to lessen the weight of its manhole covers by as much as 25 percent and achieved nearly $500,000 savings in materials costs.

The computing modeling and load testing also proved to be a boon for Big Toys, a manufacturer of play systems. They had to expand the company’s line with products built around alternative materials. Engineers at Big Toys made use of simulation capabilities in Autodesk Inventor and were able to test range of alternative materials. Scott Ramsey, marketing manager at Big Toys, cited that their average platform is made from the equivalent of 1,000 milk jugs, which didn’t end up in landfills. Whatever waste is then recycled, be it steel or plastic.

Yet another company to be benefited is Commuter Cars, maker of the Tango urban vehicle. The company’s 39-inch wide, electric Tango, owned by George Clooney, uses stainless-steel materials for the most of the parts to make sure that it can be easily recycled when Tango passes on. Moreover, SolidWorks CAD tool has helped Commuter Cars’ engineers to make parts easily and create modular designs without having to hand fit.

Going green is one of the top-notch goals for many companies like Commuter Cars and Sea Solar Power but, Chad Hawkinson, vice president, product strategy, electronics, for PTC thinks that it’s still a novel way of thinking for most engineers. But eventually, all the companies will have to think about the sustainable design goals in terms of recyclability and an energy perspective.

Via: DesignNews