For ages, cow’s excreta traditionally have been used as manure in the fields, but they are also a source of viable energy- bio gas, which can reduce greenhouse emissions, significantly.

Being used in various developing countries for over three decades now, biomass has a lot of potential to reduce carbon footprint. By capturing and storing CO2 from biogas into the ground, the biogas becomes carbon negative and scrubs our past CO2 emissions out of the atmosphere.

Booming with energy

It is a booming renewable energy sector with an average growth of 25%-30 % annually. Electricity produced from biogas is playing an integral part to the global energy market. Investments leapt to around $100bn in 2006.

In the UK, government’s drive to develop renewable resources has resulted in 600 megawatts of contracted capacity. Methane produced by decomposing organic matter in landfill sites is used to generate enough electricity to power 350,000 households. The UK is the largest market for this technology in the world. Its members are world-leaders in landfill gas technology.

Europe is coming in a big way to use Biogas, where it is being developed on a large scale for the production of fuels for stationary power generation (to be used in natural gas plants or in fuel cells) as well as for the transport sector. It is being fed into the natural gas grid (attracting subsidies) or in dedicated pipelines supplying cities. Some European countries have thousands of farm-based digesters and are producing significant quantities of biogas.

Carbon Finance, put together by World Bank for United Nation’s Clean development fund to allow rich developed nations which are not adhering to the Kyoto Protocol, to buy emissions that poor countries prevent through conserving forests or promoting renewable energy.

Nepal’s biogas programme which has overtaken China and India, per capita wise, is preventing five tonnes of carbon dioxide equivalents from being pumped into the atmosphere every year. Rich countries are buying this ‘saved’ greenhouse gas worth US $5 million for the illegal emissions they produce.

How Biogas is made?

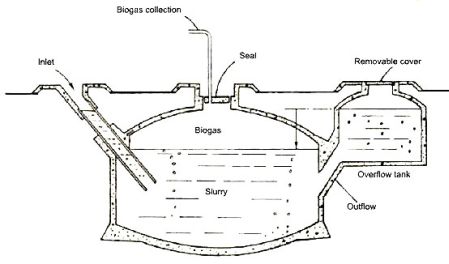

A relatively simple method, biodegradation of organic matter, be it municipal solid waste, sewage sludge or any other bio degradable waste, takes place under oxygen free conditions. The anaerobic bacteria, decomposes the organic matter and a gas which is 60% methane and carbon dioxide, is produced. It can be compared with natural gas which is 99% methane.

The origin of biogas largely affects its composition. The gas collected from a landfill site has around 50% methane.

Widely considered as CO2 neutral, the gas does not emit additional green house gases.

This saves the farmers from the problem of solid waste disposal and in turn the energy derived is a substantial form of renewable energy.

All they have to do is to collect the manure from cows and buffaloes, in a specially adapted cattle shed where they feed, mix it with water and leaves it to ferment in a large concrete tank or pit. The gas produced is collected in a simple storage tank, from where it is piped into the house to use.

Producing gas from degradable waste is great way to make best out of waste, especially in the cities where landfill waste can be directly converted into energy.

Biogas is perhaps the cheapest way to convert waste into energy. The initial cost is of about $300, for setting up a biodigester, grants for which are available in most of the countries.

The concept of biogas is more suited to systems where waste is treated near the source, there by reducing transport and initial costs.

A revolution

A few decades ago, a silent revolution took place in many developing countries of the world. Rural India, SriLanka, China, Nepal, Malaysia, Vietnam, Turkey; third world countries were facing problems with growing prices of fossil fuels and dependence on forests was affecting the ecology.

Most of the economy of these countries is still largely dependant on agriculture.

These countries have large cattle herds, producing tones of manure. Biogas, a choice which relieved poor farmers from the burden of managing tones of dung, also provided rich manure for their fields, from its residue. It came as a boon.

How it has benefited poor farmers of the Third World–

In rural India, where agricultural residues are huge and dung from India’s 300 million cattle a major problem, bio gas has become a source of energy to more than 3 million homes. Areas which were deprived of any are now self sufficient; from cooking, doing laundry to lighting, all without burning even a single piece of wood; it has even provided permanent jobs for the unemployed.

-The gas has cleanly replaced firewood, dung, agricultural residues, petrol, diesel and electricity, depending on the nature of the task, and local supply conditions and constraints. There is very little waste from it therefore making it environmentally viable.

– A smoke and ash free kitchen it has become boon for the women as it saves the time wasted in collecting fire wood and has reduced the chances of chronic respiratory diseases. Far less energy is required in making biogas than tree felling. Now the forests are also getting protected thus allowing the forests to regenerate.

– The sludge remaining after air free digestion is superior in quality, resulting in better nutrient quality of fruits and vegetables, over the usual organic fertilizer, cattle dung. Farmers can sell the produce as organic.

-Dung is no longer stored at home for cooking food, it feeds the degrader instead along with human waste. The anaerobic digestion process also destroys pathogens. As a result, sanitation has greatly improved.

-Since combustion of biofuels has become almost non existent, there are significant reductions in emissions associated with them

Biogas technology has made reduction in emissions of harmful toxins such as Sulphur dioxide (SO2), nitrogen dioxide (NO2), carbon monoxide (CO), total suspended particles (TSP’s), and poly-aromatic hydrocarbons (PAH’s).

The facts about biogas from cow dung:

Cow dung gas is 55-65% methane, 30-35% carbon dioxide, with some hydrogen, nitrogen and other traces. Its heating value is around 600 B.T.U. per cubic foot.

Natural gas consists of around 80 % methane, yielding a B.T.U. value of about 1000.

Biogas may be improved by filtering it through limewater to remove carbon dioxide, iron filings to absorb corrosive hydrogen sulphide and calcium chloride to extract water vapour after the other two processes.Cow dung slurry is composed of 1.8-2.4% nitrogen (N2), 1.0-1.2% phosphorus (P2O5), 0.6-0.8% potassium (K2O) and 50-75% organic humus.

About one cubic foot of gas may be generated from one pound of cow manure at around 28°C. This is enough gas to cook a day’s meals for 4-6 people in India.

About 1.7 cubic metres of biogas equals one litre of gasoline. The manure produced by one cow in one year can be converted to methane which is the equivalent of over 200 litres of gasoline.

Gas engines require about 0.5 m3 of methane per horsepower per hour. Some care must be taken with the lubrication of engines using solely biogas due to the “dry” nature of the fuel and some residual hydrogen sulphide, otherwise these are a simple conversion of a gasoline engine.

Modern Implications of Bio Gas

Biogas became a success in the rural because the raw material required for it is cheap. This flammable gas is mainly used for cooking and heating it is well suited to run mobile engines as well.

A biogas powered train has been running in Sweden from 2005.

T-systems a German based IT company has started using Biogas based fuel cells to keep its servers cool and is able to cut energy costs considerably.

IN the suburbs of Seattle, a fuel cell, located at the South Treatment Plant in Renton, WA, consumes about 154,000 cubic feet of biogas a day to produce up to 1 MW of electricity. That’s enough to power 1,000 households, but right now it’s being used instead to help operate the plant.

Kompogas’ Biogas facility in Otelfingen is a large scale composting facility where over 10,000 tons of material per year from about 100,000 people in the nearby community is turned into nearly 1.3 million liters of biogas.

Bio gas run vehicles have a range of 250 -400kms. Like Volvo, worldwide many vehicles are being manufactured that run on biogas. Biogas can share distribution facilites with CNG and is currently used as fuel in more than four million vehicles.

A fuel that can be replenished in 2 weeks time, is definitely worth considering over fossil fuels. Rural sector having successfully adopted the technology, it is well suited for urban areas as well where solid waste disposal has become a common problem. Rich countries are following the path shown by developing countries and soon there will more areas explored with in the biogas.